Lean Practitioner and Lean Guide

What is Lean Practitioner and Lean Guide?

Understanding the Lean principles helps one identify what is of value to the customer. This identification feeds into removing all the “waste” and keeping only what is meaningful for the customer. You can create increasingly efficient processes with reduced costs and production time. One could say that Lean is a systematic approach to minimizing waste.

Background

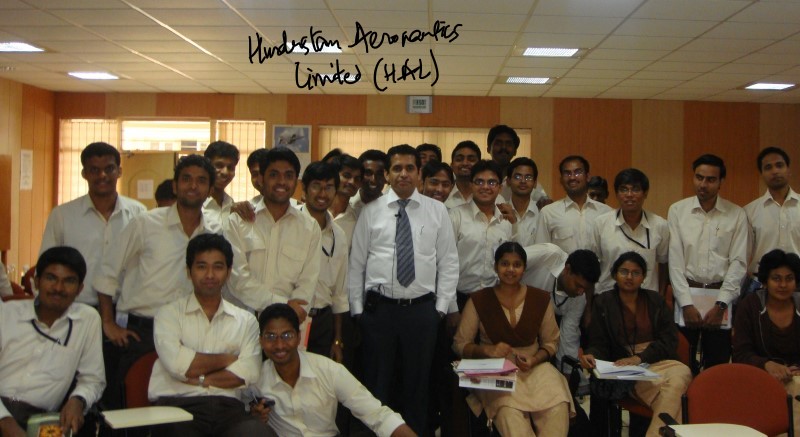

Waste Elimination in a company leads to enhanced business results. Used rigorously by Toyota as TPS (Toyota Production System) and later known as Lean Manufacturing and Lean Management, this is one program that has the highest potential for transforming a company. We have conducted this course for 24 MBB Batches in the past.

Objective

To engage participants in seeing waste, understanding reasons for wastes and elimination of wastes. To provide hands-on practice on all the common lean tools and practices.

Why Benchmark Six Sigma is suited to deliver this program?

Benchmark Six Sigma is number 1 for Lean Practitioner and Lean Guide in many ways.

- In 2001, Benchmark initiated the first business excellence certification program in India. The only other provider in India at that time was Motorola University from the USA. The program has been evolving and is reviewed and revised every year. Lean Practitioner Competencies were a part of our Green Belt and Black Belt programs

- The Lean Practitioner and Lean Guide programs were initiated in 2006

- We train the largest number of business excellence professionals in Public and Corporate programs (1500+ every year)

- The large network of business excellence professionals has now crossed 40000. You can find a Benchmark Six Sigma certified professional in every large company in India

- We moderate the largest Lean Six Sigma learning community (among the top three in the world).

- Here are 15 key elements that differentiate us from others.

Offered as

a. Public Training – Calendar Program

b. Corporate Program – Standard or Customized, Continuous or Phase wise

Who Can Benefit

- Professionals who want to learn and apply the highly popular and successful Lean Principles and Practices

- Continuous Improvement Professionals

- Process Owners and Operation Managers

- Any progressive management professional who wants to bring change for the better.

- Anyone who wants to build competence that is domain independent

Salient Features

- Facilitated by Multi-Industry Expert

- 24 Hrs of Instructor-led Classroom Training

- 24 PDUs for PMI credential

- Globally Recognized Benchmark Six Sigma Certificate

- Membership of largest Business Improvement Community

Training Package

- Course Material Kit for Lean Practitioner and Lean Guide

- Data, Templates and Case Study for Analysis

- 3 Days of Instructor-led Classroom Training

- Lean Practitioner and Lean Guide Examination

- Globally Recognized Certificate with lifetime validity

Content Outline

LEAN PRACTITIONER OUTLINE

Lean Basics

- Lean Thinking, the origin of Lean Manufacturing, the focus on continuous flow.

- The journey – Batch processing, single piece flow and pure continuous flow.

- Understanding and visualizing wastes – TIMWOOD

- The meaning of Value Add and Non-Value-Add in a practical sense.

- 5S as an improvement tool.

- PDCA cycles for continuous improvement.

- Kaizens and Kaikakus

- Identifying opportunities with As-Is Value Stream Map

Defining a mini project

- Selecting a Lean Practitioner Project.

- High-level mapping of the process – SIPOC diagram.

- Creating a mini charter.

Assessing current performance

- Lean Metrics – Cycle time, Takt time, Lead time, Throughput.

- Relationship of these metrics with each other and impact on productivity.

- Calculating process cycle efficiency.

- Working with set up and change-over times, The concept of SMED.

- Detailed mapping of a process with a swim lane map or a VA-NVA mapping

- Assessing OEE

Finding the root cause of a problem

- Gemba and Genchi Genbutsu

- Listing potential causes using an Ishikawa diagram. Using a mind mapping tool for the Cause-Effect diagram.

- Validating root causes with Why- Why analysis and Pareto’s analysis

- Using huddles and Kanban boards for team engagement during the project.

Finding alternative solutions and implementing the best solution

- Using lean principles to question the As-Is Value Stream Map

- Understanding and considering visual controls, supermarkets, Kanbans, Pull systems for the future Value Stream Map.

- Heijunka, Takt, Pitch and Runner systems.

- Visual control, Andon boards, and Kanban Boards

Ensuring Sustenance of the solution and CI after implementation

- Doing Risk Analysis

- Making use of Poka Yoke

- Using Kanban, Andon, and VSM as tools for continuous improvement.

LEAN GUIDE OUTLINE

- Implementing Lean with DMAIC framework.

- The psychology behind errors and mistake proofing

- Lean Principles

- Handling resistance

- Simulation Exercise

- VSM in Service Exercise

The contents of this program can be customized based on a shadow session or pre-study done within the company.

Request Information

To learn more about Lean Practitioner and Lean Guide Course, its uniqueness and advantages as applicable to your specific situation, fill out the fields below. You can also call +91 9811370932 (India) or +1 513 657 9333 (USA) to speak to one of our Program Advisers.

* All fields are required.

Lean Practitioner and Lean Guide programs with unmatched advantages

What everyone offers

Accreditation

Some / Industry Acceptance

Some Project Practice

Some Training Experience

Benchmark offers More

We started our programs in 2001 and most accreditations started later. We provide Exemplar Global accredited globally valid certificate.

We guide participants through cases from different industry sectors which come from real experience in those organizations.

What no one else offers

The facilitator is an International Expert on Business Excellence.

Training methodology that has matured with modifications since 2007

We integrated Lean and Six Sigma in our programs more than a decade ago.

Training is the beginning. We engage members with 2 questions every week to facilitate ongoing learning.

We provide additional coaching to our participants when they implement projects at their workplace.

The facilitator has significant training experience in manufacturing as well as services.

Use of multi-sensory approaches is our forte.

We explain the linkages of Lean with Six Sigma

A cross-industry platform for discussions available for a lifetime which has 53000+ members

Well integrated program with Business Excellence MBB

The facilitator has conducted hundreds of Lean Six Sigma programs.

The training is rated as excellent by thousands of participants.

You can expect the most engaging training experience ever.

Free Excel based templates for all our participants.

Access to online Calculators (Little’s Law, Takt Time, Process Cycle Efficiency and many others) that can be used anytime anywhere

Participants’ Feedback

Highly recommended.

Lean concepts have been explained in a very detailed way by VK Sir. Highly appreciate him for such a wonderful training. At the same time I would like to recommend extensive practice work for everyone who is going under the LPLG training program. Thanks

The course contents are very crisp & effective , learning lot of new lean tools& Techniques

This course helped me to update my skills in Lean Manufacturing.

Over all this Program is well-detailed, engaging & very useful.

Thanks to Mr.Vishwadeep for this wonderful Training.

Wonderful and interactive

A wonderful session with lots of knowledge, very interactive session with good examples to make the methodologies very clear to the crowd. Tools used for the sessions are advanced to make people involved in discussions and activities – Very detailed explanation – Fun too

Excellent training

This is the first time I am attending the benchmark six sigma training. I have gained good knowledge in Lean Sigma.

Thank you VK.

Well designed and executed training

The session was very helpful to understand the basics of lean practitioner and to think in terms of process improvement opportunities. The session had taken me to a different level where the issues or problems to resolve in a structured way. Very interactive session with a lot of examples.

In Depth Knowledge, recommended

Vishwadeep Khatri has taken us through the Lean Practitioner Training. I had got a wonderful experience in terms of learning the new techniques which will help us in our daily payroll jobs. Thank you Sir for all your knowledge transfer and surely I will try to apply some of these techniques in my process which will able to improve the process.

Useful and interesting

The sessions were very useful and interesting. We could learn how to make business/improvements through the lean. The session covered complex topics easily with realistic examples. It was an very interactive session and get an idea/direction to how to take next actions to make changes in process.

Fabulous and very informative training

Training by Benchmark Six Sigma on lean practitioners is very useful for our industries and corporate world which can make more easier for our work

Excellent Training

It was a nice session and I got a brief idea about the different mechanisms that we can use for error analysis, time management and resource allocation.

Great session

Happy to attend the session which is helpful for my career development and it brings me an idea of value-adding and Non-value adding services in our process. It was conducted by VK and shared some real scenarios that can be connected with our work environment. Overall it is a nice session. Thank you for giving me this opportunity to attend the training session.